Diecasting in Malaysia has become a crucial process in the country’s commercial community, sustaining various industries with top notch, precision-engineered elements. The approach entails infusing liquified metal, such as light weight aluminum, zinc, or magnesium, right into steel molds under high stress, resulting in long lasting and intricately designed parts. With its strategic area in Southeast Asia and well-established production infrastructure, Malaysia has become a hub for Diecasting manufacturing. The country satisfies both regional and international markets, providing elements for industries such as automobile, electronics, and construction. The accuracy, effectiveness, and scalability of die casting make it an essential component of modern production in Malaysia.

The automotive industry is just one of the largest customers of die-cast components in Malaysia, utilizing this procedure to create lightweight yet robust parts. Aluminum die casting, in particular, is extensively adopted for producing engine blocks, transmission housings, and other structural components. These components are important for lowering lorry weight, which consequently boosts gas efficiency and lowers emissions– an expanding priority in today’s sustainability-driven market. Malaysia’s die casting firms have actually spent greatly in advanced devices and processes to satisfy the strenuous standards of international auto clients. This focus on high quality and innovation has positioned Malaysia as a key vendor in the competitive auto supply chain.

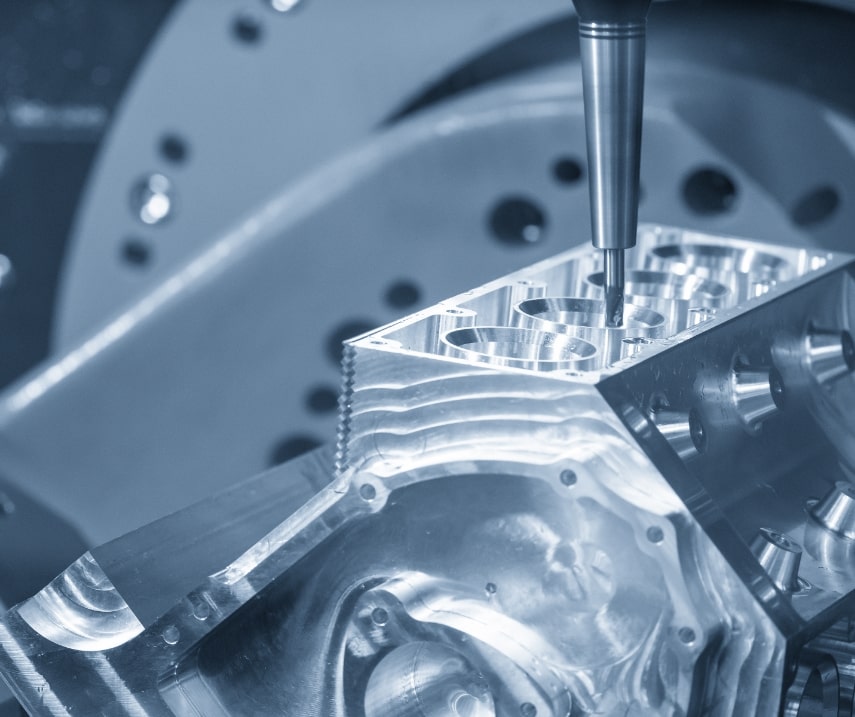

Beyond the vehicle market, Diecasting plays a substantial role in Malaysia’s electronics and telecommunications markets. The precision and reliability of the process make it ideal for producing complex parts such as heat sinks, housings, and adapters that require excellent thermal conductivity and dimensional accuracy. As Malaysia is a major exporter of digital products, the neighborhood Diecasting industry is important in supporting the global demand for premium components. Business in this industry take advantage of progressed techniques, including multi-slide casting and CNC machining, to produce complicated get rid of marginal waste. These abilities make it possible for Malaysian makers to meet the stringent needs of international markets, improving the country’s credibility for technological quality.

Sustainability has ended up being a progressively vital emphasis within Malaysia’s die casting sector, driven by environmental concerns and worldwide demands for greener manufacturing methods. Lots of companies are taking on energy-efficient modern technologies, reusing metal scraps, and enhancing processes to reduce waste and carbon exhausts. Aluminum and magnesium, commonly made use of in Diecasting, are extremely recyclable products that line up well with sustainability objectives. By recycling these metals, suppliers can considerably decrease source usage while maintaining the quality of their items. These environment-friendly methods not just add to environmental conservation however likewise give Malaysian firms a competitive edge in attracting eco conscious clients. For more information please visit here https://www.senadiecasting.com.my/

Technical innovation goes to the heart of Malaysia’s success in the die casting market. Automation and robotics are increasingly utilized to boost manufacturing effectiveness and consistency, while data-driven innovations like IoT and predictive upkeep systems help minimize downtime and enhance operational dependability. Furthermore, improvements in mold and mildew style and spreading methods have allowed makers to develop parts with higher complexity and accuracy. Government campaigns sustaining Sector 4.0 adoption have additional pushed the integration of sophisticated modern technologies, fostering an environment of continual improvement and development. These efforts make sure that Malaysia stays at the forefront of the global Diecasting market.

Diecasting is a keystone of Malaysia’s commercial abilities, underpinning the growth of vital fields such as vehicle, electronic devices, and telecommunications. The nation’s strategic investments in innovation, sustainability, and competent labor have enabled it to produce top quality parts that meet the demands of global markets. As Malaysia continues to focus on advancement and ecological responsibility, its die casting sector is well-positioned for future growth. With a solid foundation and a positive approach, Malaysia is set to continue to be a worldwide leader in precision manufacturing, driving development and sustaining industries worldwide.